Build Progress - 05/24

Few updates this month!

Signal Installs

My new batch of signals arrived, and after some assembly and programming, ended up on the layout

Signals Programmed, and Signals comissioned on the layout

One issue I had (and I called it in a previous post!) was a problem with scale. Some of the locations with a large amount of signals (Kiama) quickly hit the limit with the amount of segments I could configure in WLED.

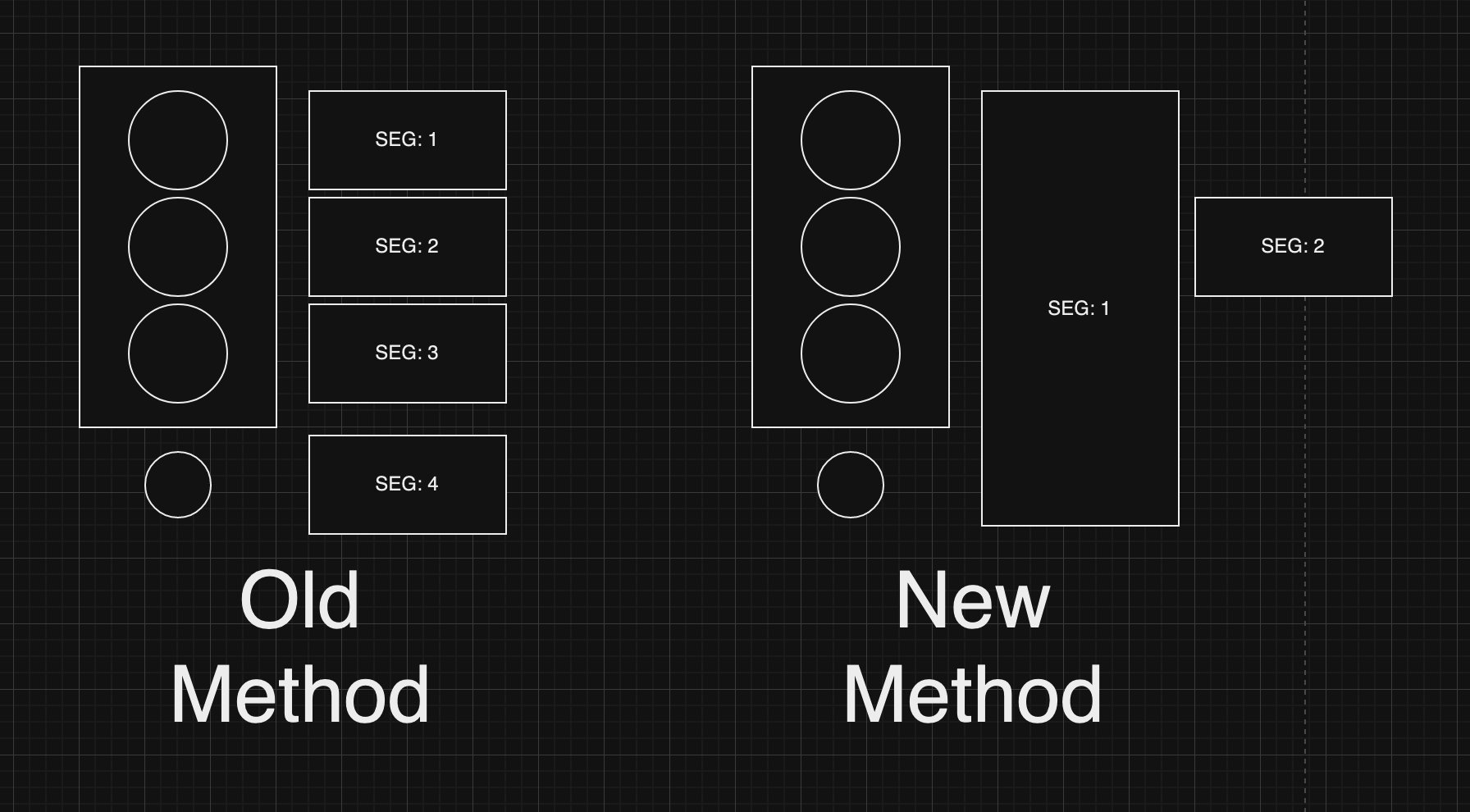

After a bit of research, I changed my tact in how I structured signals in WLED. Previously I had a single segment per lamp, with each segment being configured with the right colour/effect required. I've now changed to having a single segment for the whole signal head, and an additional 'sub-segment' that controls any lamps with an attached effect - such as blink.

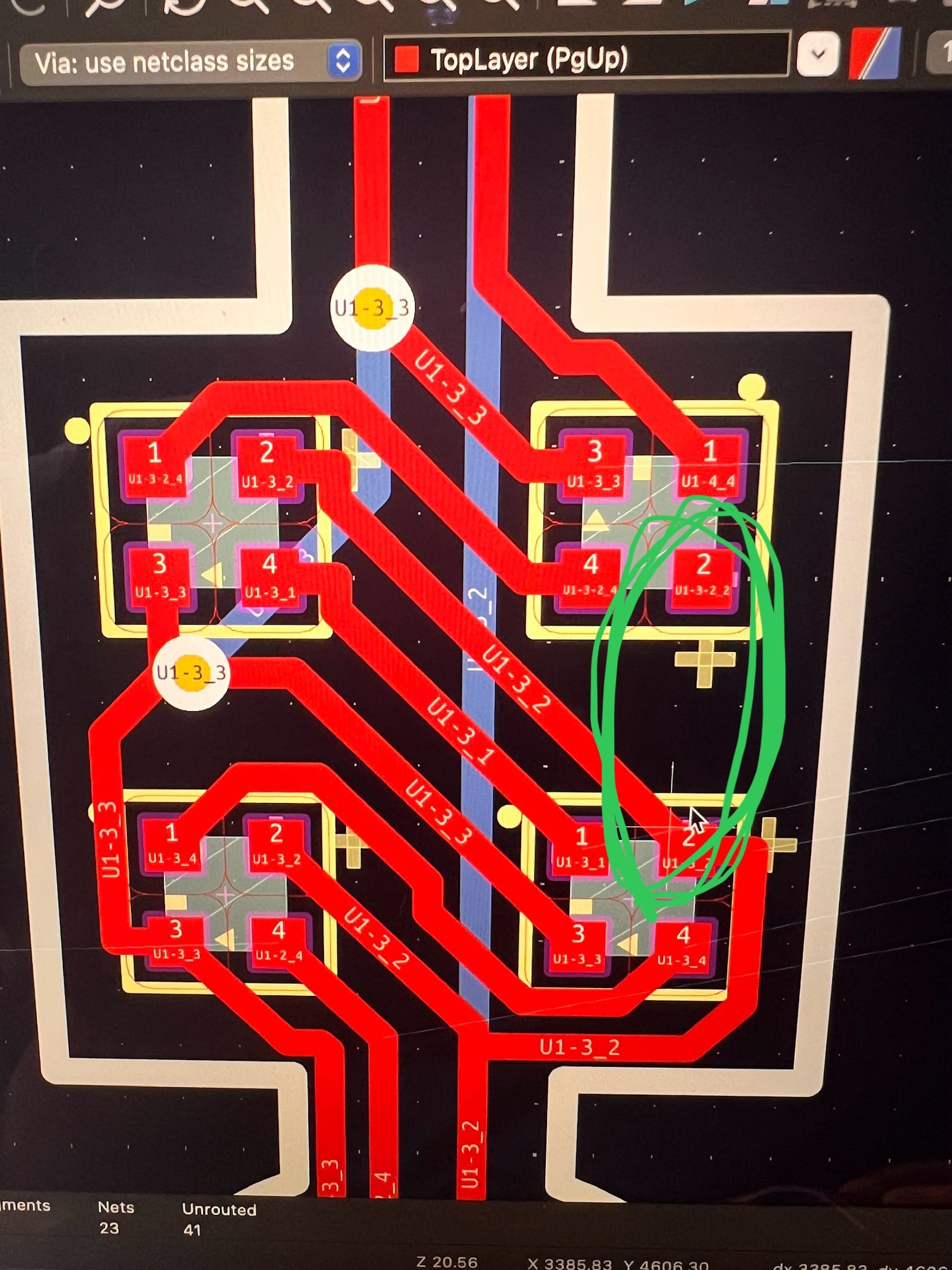

so now, a typical JSON payload looks like this:

{ "seg": [

{

"id": 0,

"i": ["0","0","0","ff0000","ff0000","0","0"],

"frz": true,

"on": true

},

{

"id": 1,

"frz": true,

"on": false

}

]

}this is an example of two segments (address 0 and 1) - segment 1 has a blink effect attached. When displaying Stop (this aspect) we set the "i" attribute from the bottom of the signal based on the LED layout from the bottom to the top of the signal, as they are wired in a daisy chain. 0 means off, ff0000 is red. So above, we have the lower lamp of the main head, and the marker lit.

Where we need to flash, we set on: false on the first segment, and on:true on the second. Much easier!

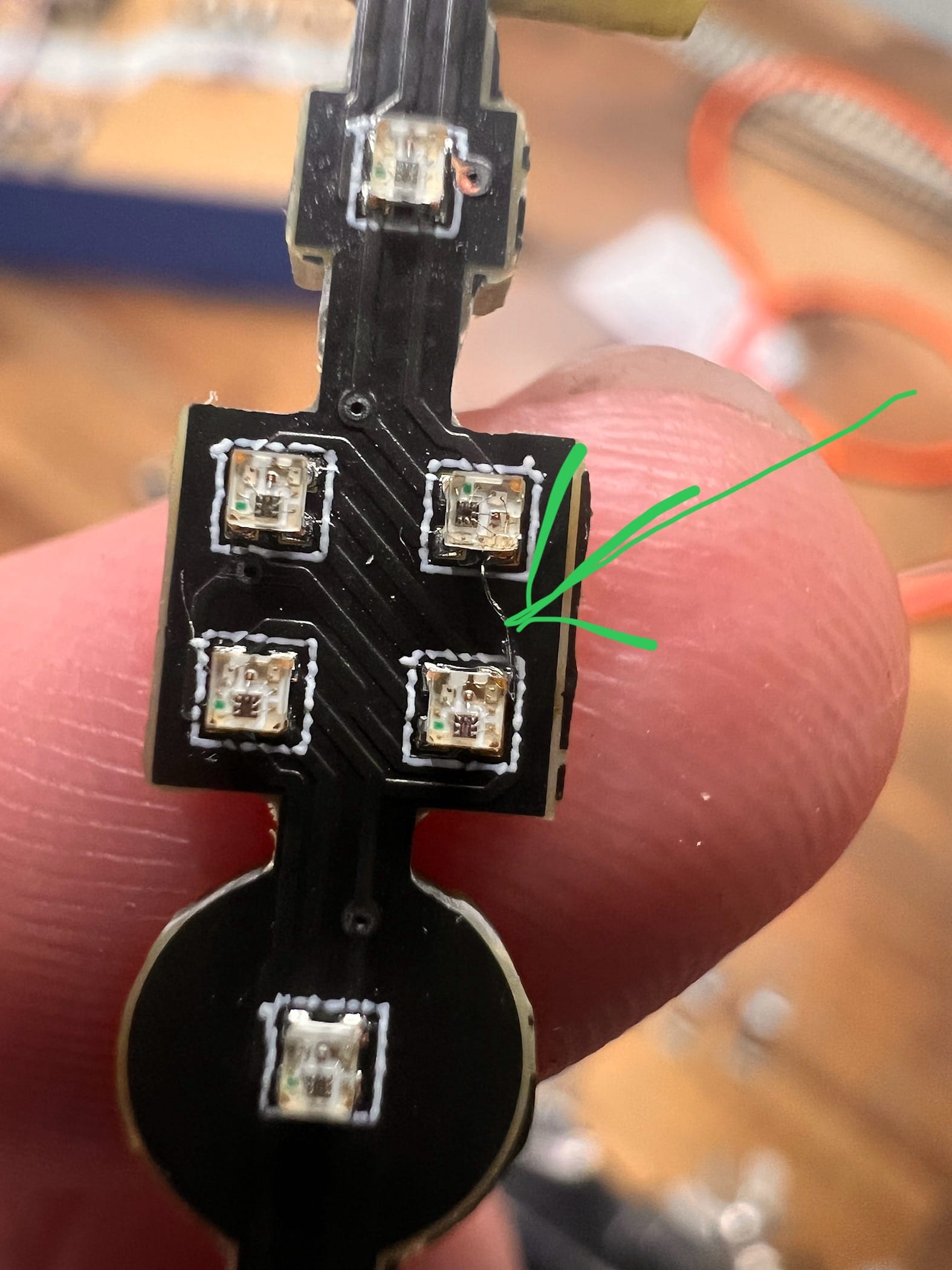

I also stuffed up one of my PCBs, and inadvertently missed a trace. With my optivisor and a pair of tweezers, I was able to rectify the fault. Glad I only had the one signal to do!

the culprit, and the fix

More Cabling | PHC001 inches past a shunt aspect at the country end of Kembla Junction.

Preparing for Operations

Now the track is largely complete, I'm slowly turning my focus to operations. I've now had two shakedown sessions where I haven't run a full schedule, but have tried to add a few elements to build out the picture of what a full blown session might look like.

The first session I tried jobs generated using a Mac app called Switchlist. I started to really like this app, and having the ability to print job sheets, and hand out clipboards was really cool. However, I rapidly started to hit the walls of how I wanted some jobs to run.

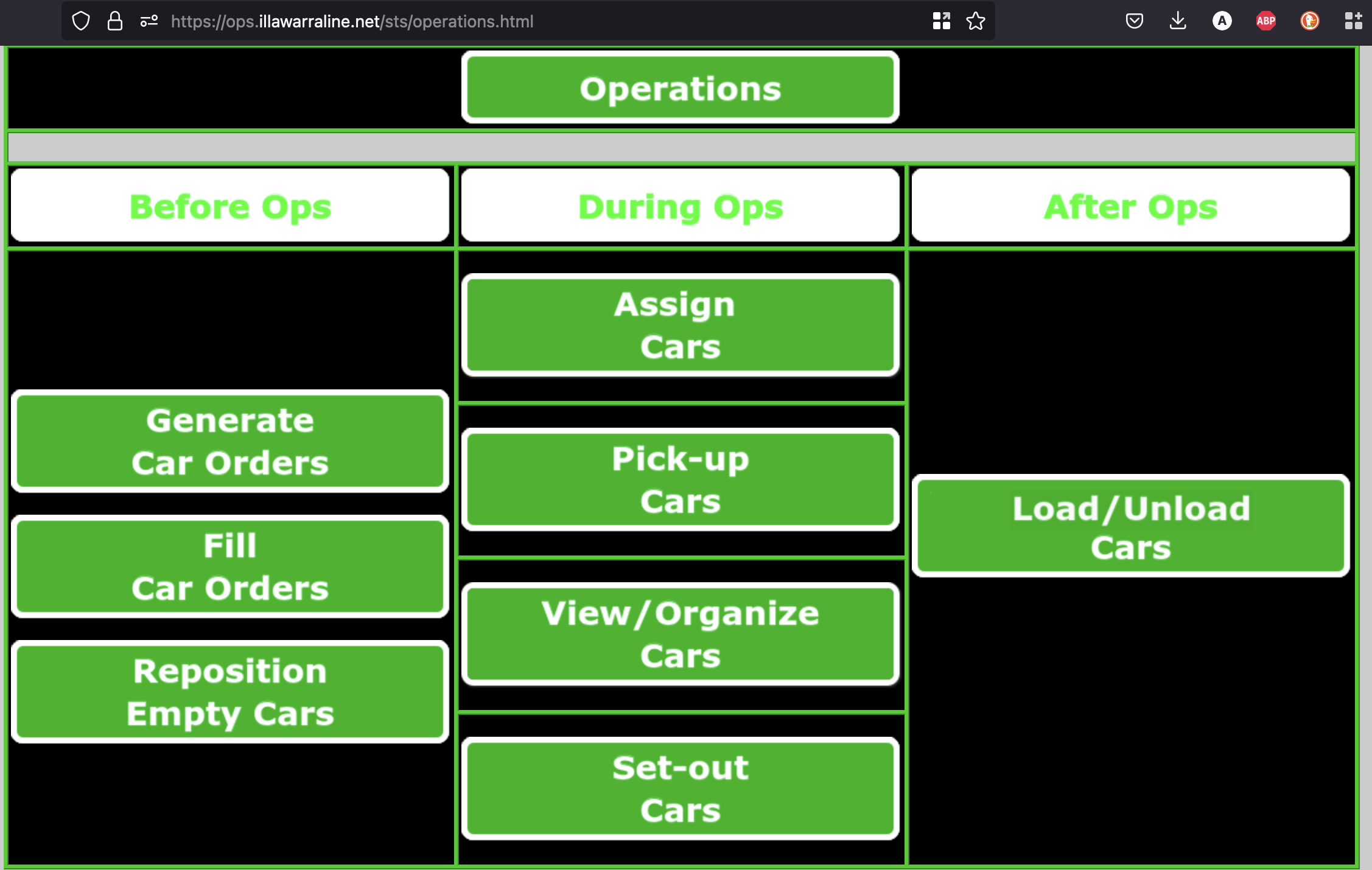

After searching online I stumbled across STS - the Shipper-driven Traffic System. Its a simple webapp that runs in PHP, with an SQL backend. I spent a good half a day trying to unpick the logic and understand how it works (and the doco was great!) - and started to realise this was actually a better approach for I wanted.

In a really quick summary - STS works like this:

- You generate car orders for an industry

- You assign cars to those orders

- You assign those cars to trains servicing that industries

- Operators then pickup, move and set down cars during a session

What I like about STS is its ability to decouple a lot of layout properties from handling traffic on the layout - this becomes the operators responsibility.As an example - STS doesn't care about siding lengths, or car lengths. You as an operator or session host handle that in your own way.

So I've bought a few 7" tablets and stuck this behind a reverse proxy/ssl to make it easy to use by operators.

We gave this a go in shakedown session 2, and overall I think it did the job it needed to. I've yet to look at passenger operations, but it'll be next once I get this freight flow and schedule right.

Remote Dispatching

Shakedown session 2 we included a remote dispatcher. Using Parsec to remote into the layout PC (super low latency!) I also bought some radios to use with Zello

Our dispatcher was two states away, but with a decent internet connection we were able to get reliable comms (he used the Zello app on his phone) and with STS running on one window, and the panel on the other - I think it worked well. I'm really keen to see this role becoming integral to the session in the future, especially once the whole line has a safeworking element of some sort. There are about 3-4 signals left to install, and I'll start working on the miniature electric staff system next.

So that's about it, a lot of stuff going on but I'm looking forward to having regular sessions soon. I've got a few things I want to tackle in the short term:

- Little shelves for the tablets

- RFID-based safeworking system to emulate miniature electric staff south of Kiama

- Operating Sessions!